1, siv cov khoom yas tshwj xeeb, muaj peev xwm tiv thaiv corrosion, tuaj yeem lav qhov kev sib cais ntawm cov zaub mov.

2, raws li cov duab ntawm cov neeg siv khoom thov, koj tuaj yeem hloov kho cov biscuit abrasive.

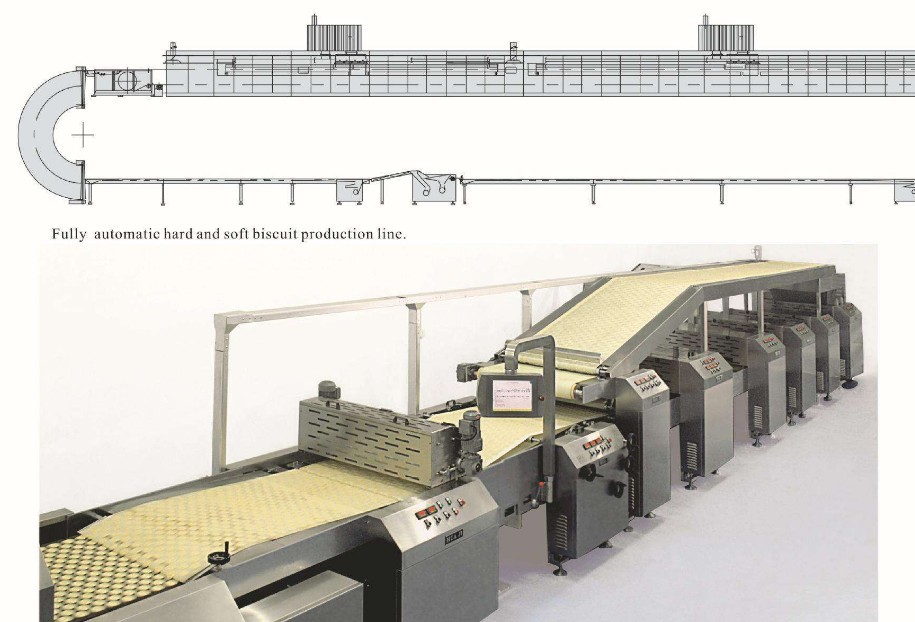

A: Taw qhia rau cov kab ntau lawm biscuits

Hom Tsis Siv Neeg Biscuit Ntau Lawm Kab no yog tsim los ntawm lub tuam txhab kev zom thiab nqus ntawm Japanese tshuab.Cov cuab yeej muaj cov qauv tsim tshiab, cov qauv compact, thiab qib siab ntawm automation, los ntawm kev pub dov, molding, khib nyiab rov ua dua, ziab, roj txhaj tshuaj, thiab cua txias.Ua tiav tsis siv neeg ib zaug ua tiav, lub tuam txhab muab cov neeg siv nrog ntau pua pwm thiab ntau ntau cov txheej txheem zaub mov txawv.Los ntawm kev hloov cov pwm thiab cov txheej txheem cov zaub mov txawv, nws tuaj yeem tsim ntau yam khoom noj khoom haus high-end nrov ntawm kev ua lag luam, xws li qab zib biscuits, qhaub cij biscuits, ultra-nyias biscuits., dej qab zib crackers, tsiaj biscuits, ncuav qab zib multi-dimensional, zaub biscuits, thiab lwm yam.

B: Technical Parameters

| Tus Qauv Qauv | LZB-400 |

| Qhov hluav taws xob | 380v / 50hz |

| Nruab lub zog | 120KW (Kev siv hluav taws xob tiag tiag yog 110KW) |

| Ci kub | 200-300 ℃ |

| Ua haujlwm dav | 9 50mm |

| Muaj peev xwm ntau lawm | 150-200kg / h |

| Cov kab ntau lawm ntev | 43m ua |

C: Cookies process flow:

Pretreatment ntawm raw khoom - ua khob noom cookie - dov mov paj - ncuav mog qab zib nias - ci - roj txhaj - txias

D: nta

1, biscuit forming party: Cov cuab yeej muaj peb ntu: tawv ua, molding thiab recycling ntawm cov khoom seem;

2, ib zaug yob txoj kev, siab molding tus nqi, zoo molding zoo.

3, thaum hloov cov khoom specification, tsuas yog yuav tsum tau hloov lub impression roller.

4, qhuav lub thawv txoj kev sub-section los ua ke, yooj yim rau nruab thiab thauj.

5, ziab lub thawv: mesh siv rauv nrog stainless hlau mesh coj cov khoom, ci nyhuv yog zoo.

6. Injector txais zaus converter los tswj kev ceev, ruaj khov ceev thiab zoo zog-txuag nyhuv.

7, roj injector: lub taub hau lub taub hau tuaj yeem hloov kho.

8. Ib feem ntawm lub tshuab uas tiv tauj cov zaub mov yog cov hlau tsis muaj steel, uas ua tau raws li kev nyiam huv ntawm cov zaub mov.

1, siv cov khoom yas tshwj xeeb, muaj peev xwm tiv thaiv corrosion, tuaj yeem lav qhov kev sib cais ntawm cov zaub mov.

2, raws li cov duab ntawm cov neeg siv khoom thov, koj tuaj yeem hloov kho cov biscuit abrasive.

* Kev nug thiab kev pab tswv yim.

* Kev txhawb nqa kev sim ua qauv.

* Saib peb lub Hoobkas, muab kev pabcuam.

* Kev cob qhia yuav ua li cas rau nruab lub tshuab, kev cob qhia siv lub tshuab.

* Cov engineers muaj rau kev pabcuam tshuab txawv teb chaws.

1.Lub sijhawm lav ntawm lub tshuab yog dab tsi?

Ib xyoos.Tsuas yog cov khoom hnav, peb yuav muab kev pabcuam dawb rau cov khoom puas tsuaj los ntawm kev ua haujlwm ib txwm nyob hauv warranty.Qhov kev lees paub no tsis suav nrog kev hnav thiab tsim kua muag vim kev tsim txom, kev siv tsis raug, kev sib tsoo lossis kev hloov pauv lossis kho tsis raug cai.Kev hloov pauv yuav raug xa tuaj rau koj tom qab muab cov duab lossis lwm yam pov thawj.

2.Qhov kev pabcuam koj tuaj yeem muab ua ntej muag?

Ua ntej, peb tuaj yeem muab lub tshuab tsim nyog tshaj plaws raws li koj lub peev xwm.Thib ob, Tom qab tau txais koj qhov kev cob qhia qhov loj me, peb tuaj yeem tsim lub rooj cob qhia tshuab layout rau koj.Thirdly, peb tuaj yeem muab kev txhawb nqa ob qho tib si ua ntej thiab tom qab muag.

3.Koj tuaj yeem lav qhov kev pab cuam tom qab muag li cas?

Peb tuaj yeem xa cov engineers los coj cov kev teeb tsa, commissioning, thiab kev cob qhia raws li daim ntawv cog lus kev pabcuam peb tau kos npe.